Organizations and Markets in Emerging Economies ISSN 2029-4581 eISSN 2345-0037

2023, vol. 14, no. 3(29), pp. 696–720 DOI: https://doi.org/10.15388/omee.2023.14.11

Hybridizing Technology Management and Knowledge Management to Spur Innovation: A System Dynamics Approach

MRS Suryanarayana Reddy

Department of MBA, K G Reddy College of Engineering & Technology, India

drsnreddy@kgr.ac.in

https://orcid.org/0000-0001-9337-9942

Muddangala Naresh Babu

School of commerce and Management, Mohan Babu University, India

nareshbabu.m@vidyanikethan.edu

https://orcid.org/0000-0001-8402-5309

Gundraju Yamuna

School of Commerce and Management, Mohan Babu University, India

yamuna.g@vidyanikethan.edu

https://orcid.org/0000-0002-1530-0503

Thaya Madhavi

School of Commerce and Management, Mohan Babu University, India

madhavi.t@mbu.asia

https://orcid.org/0000-0002-9635-3841

Cristina Claudia Bizon

Doctoral School, Bucharest University of Economic Studies, Romania

crystinaclau@yahoo.com

https://orcid.org/0000-0002-7029-7378

Nicu Bizon (corresponding author)

The National University of Science and Technology POLITEHNICA Bucharest, Pitești University Centre, Romania

nicubizon@yahoo.com

https://orcid.org/0000-0001-9311-7598

Phatiphat Thounthong

Renewable Energy Research Centre (RERC), Department of Teacher Training in Electrical Engineering, Faculty of Technical Education, King Mongkut’s University of Technology North Bangkok

phatiphat.t@fte.kmutnb.ac.th

https://orcid.org/0000-0002-1453-4236

Abstract. The purpose of this research is to identify the drivers of innovativeness in a furniture manufacturing company. The scenario is the business environment where the hybridization of Technology Management (TM) and Knowledge Management (KM) is operative to promote innovation. The elements of the Technology Acceptance Model (TAM) and Socialization-Externalization-Internalization-Externalization (SECI) Model of KM have been modeled and used for simulation for the identification of the role played by the factors influencing the furniture design information conversion rate. The research follows the case study method to research as it draws data from a single company. Data from a multinational furniture manufacturing company that has over 10,000 products and operates in 24 countries have been used for simulation purposes. Results have shown that among the five factors that influence information conversion rate, the company should focus on correction efficiency and calculation efficiency enhancement if the aim is to maximize product and process innovations; and enhance contextualization efficiency if the priority is immediate results of innovativeness improvement. The results have also shown that about 615 innovative products and processes can be produced in six months by improving the correction efficiency to 80%. The theoretical implication of the study is in the form of a model which can be used by innovative companies to identify the critical factors that influence innovativeness, and the practical implications are in the form of suggestions to the managers of the furniture manufacturing company to enhance their innovativeness so as to gain competitive advantage in business.

Keywords: innovation, furniture manufacture, knowledge management, technology management, modeling and simulation, information conversion

Received: 13/2/2023. Accepted: 27/10/2023

Copyright © 2023 MRS Suryanarayana Reddy, Muddangala Naresh Babu, Gundraju Yamuna, Thaya Madhavi, Cristina Claudia Bizon, Nicu Bizon, Phatiphat Thounthong. Published by Vilnius University Press. This is an Open Access article distributed under the terms of the Creative Commons Attribution Licence, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

1. Introduction

Innovation has become the key driver of business in the current knowledge-driven economy. “The context of this research is furniture design, which is a highly creative field owing to its bearing on the ever-changing tastes of customers from time to time.

Innovation has always been the driving force behind progress in various industries, pushing boundaries, and ushering in transformative changes. As we step into the 21st century, the furniture industry stands at the threshold of a new era of innovation, poised to redefine the way we interact with and experience the spaces we inhabit. This exciting and dynamic landscape calls for a deeper exploration, a quest to unravel the untapped potential within the realms of furniture design and manufacturing. The furniture industry, with its rich history, has traditionally been synonymous with craftsmanship and functionality. However, the winds of change are sweeping through this age-old domain, as technological advancements, evolving consumer preferences, and environmental concerns converge to shape a future that is innovative, sustainable, and captivating. It is within this context that the motivation for research in innovation within the furniture industry comes to life. These driving forces are the main motivation to this research, which aims to hybridize the technology management and knowledge management to spur innovation.

The furniture industry has witnessed significant innovation in recent years, driven by various factors including technological advancements, changing consumer preferences, sustainability concerns, and the desire for more functional and aesthetically pleasing furniture solutions. The context of innovation in the furniture industry is multifaceted. The integration of technology into furniture has led to the development of smart furniture. This includes items like sofas with built-in speakers and charging ports, tables with wireless charging capabilities, and beds with adjustable features controlled via smartphone apps. Smart furniture enhances convenience and connectivity in modern living spaces. With growing environmental awareness, there is a strong emphasis on sustainable and eco-friendly materials in furniture design. Innovations in this area include the use of recycled materials, bamboo, reclaimed wood, and sustainable production processes to create furniture that is both stylish and environmentally responsible. Urbanization and the trend toward smaller living spaces have driven the demand for modular and space-saving furniture. Innovations in this category include expandable tables, modular shelving units, and multi-purpose furniture pieces that can serve multiple functions within a compact footprint. The 3D printing technology has opened up new possibilities in furniture design and manufacturing. It allows for the creation of intricate and customizable furniture pieces that were once difficult or impossible to produce using traditional methods. This innovation enables personalization and unique design choices for consumers. Furniture designers now use advanced digital design and visualization tools to create and refine their products. Computer-aided design (CAD) software, virtual reality (VR), and augmented reality (AR) are used to design and preview furniture, enabling designers to experiment with new shapes, materials, and styles. Many furniture companies offer online customization tools that allow customers to personalize their furniture. Customers can choose from various options such as fabric, colour, size, and design elements to create furniture that suits their preferences and space. Furniture companies are increasingly collaborating with renowned designers and architects to create unique and iconic furniture collections. These partnerships bring fresh perspectives and innovative designs to the market. Innovations in materials science have led to the development of high-performance and durable materials, such as engineered woods, advanced foams, and metal alloys. These materials contribute to the longevity and quality of furniture. There is a growing trend toward minimalist and contemporary furniture designs characterized by clean lines and simplicity. This design approach emphasizes functionality and aesthetics, often with a focus on sustainability. In the office furniture sector, ergonomic innovation is critical. Furniture companies are designing office chairs, desks, and workstations that can be customized to fit the unique ergonomic needs of individuals, promoting comfort and well-being in the workplace. AI and automation are being used in furniture manufacturing to streamline production processes, reduce waste, and improve quality control. These technologies enhance efficiency and consistency in furniture production. Some companies are exploring virtual try-on experiences using Augmented Reality (AR) technology. Customers can visualize how furniture will look and fit in their spaces before making a purchase, reducing the risk of dissatisfaction. The furniture industry is undergoing a transformation driven by innovation in materials, design, technology, and sustainability. These innovations are shaping the future of furniture, making it more functional, aesthetically pleasing, and environmentally responsible to meet the evolving needs and expectations of consumers.

While there are several studies that have focused on the efficiency, efficacy, and effectiveness of technology management and knowledge management on an individual basis, not many have attempted the hybridization of both of these management tools in creative fields. Even those studies that have researched on hybridizing of technology and/or management have focused on hybridizing technology readiness with technology acceptance (Acheampong et al., 2017), cost saving with technology adoption (Ullah et al., 2022), and design and management of technology (Casciani et al., 2021).

2. Review of Literature

The role of innovation in the present-day manufacturing and service industries has been realized more than ever before.

The findings from the research by Georgieva et al. (2023) suggest that Bulgaria’s furniture sector is not widely perceived as innovative, and Bulgarian furniture manufacturers do not actively engage in partnerships with the IT and mechatronics industries. These companies tend to avoid involvement in Global Value Chains (GVCs), as they perceive them mainly as supply chains. Consequently, they have a reduced susceptibility to disruptions within these chains. Moreover, businesses tend to keep their innovations confidential, possibly contributing to the limited collaboration between furniture manufacturers and academic institutions, non-governmental organizations (NGOs), and other pertinent entities.

Xiong et al. (2023) focused on the examination of the present state, technical capacities, and emerging trends within the Chinese smart furniture sector. By combining a thorough literature review with on-site investigations and an analysis of significant scientific research initiatives in Zhejiang Province, China, a comprehensive evaluation and discussion regarding prior experiences, distinguishing characteristics, technologies, products, and control methodologies within the smart furniture industry in China were conducted. The primary technologies prevalent in the current Chinese smart furniture sector encompass embedded systems, sensors, short-range wireless communication, artificial intelligence, and intelligent interaction methods. This research also addresses the challenges and prospects that the industry faces while highlighting strategies for innovation and securing a dominant position in the furniture market during the shift from the traditional furniture industry to the era of intelligent enhancement.

Cheng et al. (2023) have observed the proliferation of digital technologies within enterprises resulting in significant transformations in the way knowledge is managed. They conducted research to explore the mechanisms and consequences of knowledge digitization (KD) on a company’s innovation performance (IP). The study introduced the concept of KD, which is characterized by its codability, convergence, and generativity. The survey involved 238 Chinese furniture companies with a digital foundation and tested hypotheses using structural equation modelling. The results indicate that these characteristics have a positive influence on IP. Moreover, knowledge advantage (KA) acts as an intermediary factor between KD and IP. This discovery not only enhances the understanding of the relationship between digital technology and knowledge management but also addresses the existing gap in the understanding of the role played by KD. Furthermore, it offered valuable insights for knowledge-intensive industries seeking to advance digital transformation, implement KD strategies, and gain a competitive edge.

There are studies on the furniture industry in the context of small and medium-sized enterprises (SMEs). Zighan and Dwaikat (2020) did research based on semi-structured interviews conducted with 53 SMEs in the furniture manufacturing sector in Jordan, which revealed that SMEs generally lag behind larger organizations in terms of adopting agility. SMEs encountered numerous constraints related to resources, with financial challenges emerging as a major impediment to the enhancement of their agility. The study findings highlighted that manufacturing SMEs can bolster their agility by effectively harnessing the skills and capabilities of their workforce, resulting in a significant and simultaneous improvement in organizational agility. Furthermore, the research results suggested that factors such as customer orientation, service provision, and strategic collaboration exert a considerable impact on the development of agility among SMEs.

Through research undertaken by analyzing data from 203 hotel managers, it was proved that innovation mediates between customer orientation and business performance (Casciani et al., 2021). In another study by Grissemann et al. (2013) in small and medium-sized enterprises (SMEs) of consumer goods, it was shown that innovation was the key to the gaining of competitive advantage in business. Cefis and Marsili (2006) based on the research conducted in manufacturing firms in the Netherlands concluded that innovation acts as a survival tool of business and its impact is higher with the age of the firm. Empirical evidence gathered from 259 firms has proved that the innovation capabilities of a firm enhance customer participation, which in turn results in better business performance (Ngo & O’cass, 2006). It has been proved through a sample size of 150 firms that innovation acts as a moderator between digitalization and business performance, provided the digitalization is aligned with the innovation strategy (Fernández-Portillo et al., 2022). Thus, there is research evidence that technology and knowledge management should spur innovation in the organization to ensure its sustainability.

Peykani et al. (2022) have used the fuzzy front-end concept, fuzzy data envelopment analysis model, and adjustable possibilistic programming approach to identify the efficiency of innovation in business performance and proved that by its very nature, innovation is full of uncertainty and low efficiency. So, a strategic approach of matching business and technology goals was strongly recommended. Limsangpetch et al. (2022) conducted empirical research using a sample size of 200 employees of the IT sector and proved that knowledge management comprising knowledge acquisition, storage, sharing, and application correlated to business performance through a mediating role of organizational innovation. Lai et al. (2022) have proved that both KM and knowledge management system (KMS) performance have positive significant influence on innovation performance and business performance, and further, innovation performance has positive influence on business performance. Donate and de Pablo (2015) conducted research in four innovative manufacturing industries in Spain using a sample size of 111 and found that knowledge-oriented leadership in the KM practices significantly promoted innovation. More specifically, the study revealed that the KM practices—creation, transfer, storage, and application when supported well through knowledge-oriented leadership can lead to product innovation. Acosta-Prado et al. (2020) considered 102 Colombian new technology-based firms for the study of the relationship between KM and innovation. The study revealed that flexible structure, state-of-the-art information and communications technology, strategic purpose, and competitive environment that supported KM were essential for bringing innovative technologies.

There are hardly any studies that have combined TM with KM and determined the hybridized influence of both of these on innovation. Among the few studies which have tried to integrate TM and KM, Lin and Huang (2008) utilized the task technology fit (TTF) theory and social cognitive theory (SCI) to provide an integrative approach. A sample of 192 users of technology in knowledge-intensive organizations was chosen for the empirical study. The study revealed that task interdependence, user-experienced task-technology fit, self-efficacy of the system in use, and outcome expectations of the user were crucial to the success of KM and TM integration. Further, they emphasized that the KM strategy and TM strategy need to be aligned well towards a common goal. Koster (2022) tried to study the resources capabilities in promoting innovation performance of an organization through the data collected from 673 knowledge-intensive organizations in the Netherlands. Through the study, it was revealed that learning capabilities enabled through technological resources can enhance innovation performance. Further, granting work autonomy to the employees was found to enhance creative abilities, which in turn promoted innovation. Gloet and Terziovski (2004) found that to promote innovation performance, there should be a good combination of ‘soft HRM practices’ and ‘hard information technology practices’ as observed through the empirical research in 70 employees from manufacturing companies in Australia and New Zealand that included both private and public sector companies.

Heydari et al. (2021) have developed an integrative framework of KM and TM in the context of the banking industry. Having realized the necessity of developing a database for customer KM, customer relationship management, and effective TM, the research identified the elements which formed the integrative model considering the Iranian banking industry as the reference. It was observed that phenomenon-orientation, causation of associated variables, contextual factors, moderating conditions, and strategies were identified to be the crucial elements that need to be considered during the development of the integrative model.

Isinkaye and Soyemi (2021) considered the integration of KM and TM in the portable interactive learning system. This study identified that relevant technologies in seeking knowledge, creating knowledge, managing knowledge, and managing feedback play an important role during the integration process. It was recommended that the rule-based inference method of the program may be necessary to connect the elements of the integrative model so that technology may act as an enabler to learning.

Wang et al. (2023) examined the effect of business process digitization on firm innovation performance and found that business process digitization has a positive effect on firm innovation performance, knowledge search plays a mediating role between business process digitization and firm innovation performance, and digital culture has a positive moderating effect, which is mainly reflected in business process digitization and boundary-spanning search. Silva et al. (2022) investigated the role of knowledge management practices in the absorptive capacity in soybean farms and found that knowledge management practices were identified as the link between potential and realized mechanisms that affect absorptive capacity insofar as they have institutionalized the process of creating an organizational memory.

The relation between technology and knowledge management is similar to the link between tools and the mind; for instance, the reason uses the tools to transfer and explain the idea of reducing waste during manufacturing, and KM at this point uses technology for the transfer and exchange of knowledge. While it looks very simple at a glance, there are a whole lot of processes and techniques that are involved in linking the two, and it must be feasible, and cost justification should also be known beforehand. Hybridizing these two concepts adds to complications in many different forms. Design information conversion rate involves calculation, condensation, contextualization, and correction that have to be made so that over time the perceived usefulness of the design improves in a continuous manner. Similarly, when the company innovates through the efficient KM processes, both the tacit and explicit knowledge contribute to design knowledge growth rate and design knowledge advancement rate. A more detailed explanation to this is provided in the model development section.

While there are many such studies in similar lines, there is no evidence of a study leading to the hybridization of both KM and TM in the context of innovation.” This is the main research gap observed in the research, and our research has the main objective of identifying the critical parameters of TM and KM which can contribute to the innovativeness of an organization.

There is a strong reason for selecting a single leading furniture manufacturing company for simulation purposes. A leading company serves as an excellent reference for hybridizing knowledge management and technology management to drive innovation in the furniture manufacturing industry for several compelling reasons. The company will have a history of introducing innovative furniture designs and concepts to the market. Their ability to continually develop new and unique furniture products demonstrates a strong connection between knowledge management (capturing design and market insights) and technology management (using advanced manufacturing technologies). The leading company operates on a global scale with a presence in numerous countries. Managing knowledge and technology across diverse markets and regions requires a sophisticated approach. The company’s success in this regard can provide valuable insights for other furniture manufacturers looking to expand internationally. The company revolutionizes the furniture industry with its flat-pack furniture, which reduces transportation costs and environmental impact. This innovation required a deep understanding of both manufacturing technology and efficient logistical processes, demonstrating the synergy between knowledge and technology management. The company will place a strong emphasis on understanding customer needs and preferences. This knowledge-driven approach informs their product development and technology choices, ensuring that innovations are aligned with customer expectations. Thus, a leading company with these features would be an ideal model for simulation purposes.

3. The Research Methodology

3.1 The System Dynamic Methodology

System Dynamics modelling and simulation is a methodology used to analyse complex systems over time. It is particularly valuable for studying dynamic systems where various factors interact and influence each other. A brief overview of the methodology is as follows:

Problem Formulation: The first step is to clearly define the problem or system you want to study. This involves identifying the key components, variables, and relationships within the system. A clear problem statement and objectives are crucial.

Conceptualization: In this phase, a conceptual model of the system is developed. This includes creating a causal loop diagram that illustrates how variables in the system interact with each other. Causal loops capture both reinforcing (positive feedback) and balancing (negative feedback) feedback loops.

Model Building: With the conceptual model in place, building a mathematical representation of the system using differential equations or difference equations will be undertaken. These equations describe how variables change over time based on the interactions defined in the causal loop diagram.

Data Collection: Data to parameterize and validate the model will be gathered. This may involve historical data, expert opinions, or experimental data, depending on the nature of the system.

Model Calibration: The model parameters are tuned to ensure that it accurately reflects the behaviour of the real system. Calibration often involves comparing model outputs to historical data to fine-tune the model.

Simulation: Once the model is calibrated, simulations are run to explore how the system behaves over time. System Dynamics software allows you to set initial conditions and run simulations under various scenarios. These simulations generate dynamic behaviours and insights.

Sensitivity Analysis: Sensitivity analysis helps identify which parameters or variables have the most significant impact on the system’s behaviour. It helps in understanding key drivers and uncertainties in the system.

Policy Testing: System Dynamics models are valuable for testing the impact of different policies or interventions. By changing variables or parameters in the model, one can simulate the effects of different policy decisions.

Scenario Analysis: Various scenarios to assess potential outcomes under different conditions are undertaken. This is particularly useful for long-term planning and decision-making.

Model Validation: Continuous validation is essential to ensure that the model accurately represents the real system’s behaviour. If discrepancies arise, the model may need adjustments.

Communication: The results and insights gained from the simulations are communicated to stakeholders or decision-makers. Visualization tools, such as graphs and charts, are often used to present the findings effectively.

Iterative Process: System Dynamics modelling and simulation are often iterative processes. As new data becomes available or the system evolves, the model may need updates and refinements to remain relevant and accurate.

System Dynamics modelling and simulation provide a holistic view of complex systems, helping decision-makers understand the long-term consequences of their choices and policies. It is a valuable tool for tackling dynamic and interconnected problems in various fields, including business, economics, environmental management, and public policy.

3.2 The Model Development

The model (Figure 1) was developed based on the data collected from an innovative organization that has a proven track record of using the latest knowledge and technologies in home furnishing and has both the KM and TM strategy aligned to the business strategy. The company is internationally known for its home furnishing goods with about 10,000 products that include home furniture and accessories. Customers can order almost all the range of products online. The company has 253 stores across 24 countries and 32 stores run by franchises, and has welcomed over 500 million visitors to the stores and over 400 million visitors on their websites. The sales had crossed 20 billion Euros in 2018, and a growth of about 7% per year has been recorded to date.

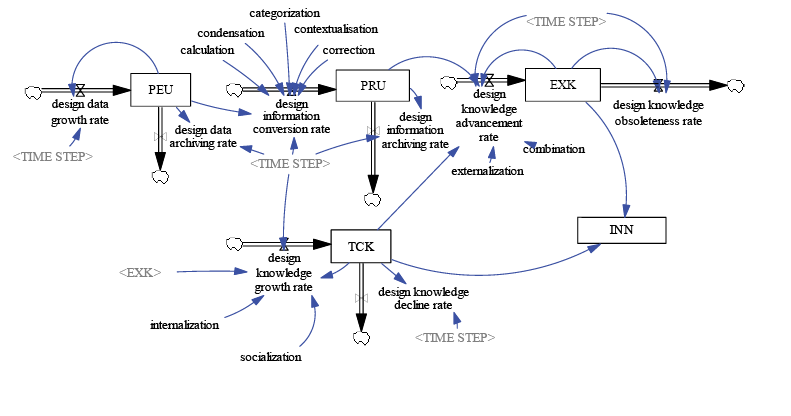

Figure 1

The Hybridized Model of Technology and Knowledge Management

The success of the furniture design industry is mainly based on the technologies they use for the marketing and manufacturing of their products and services. “There are several technologies that are used by the furniture design industry under consideration. Image-scripting technology (Lee, 2016) is one such technology that is used to produce photorealistic images of furniture products. This technology enables potential customers to visualize the furniture in many different colors and rotate the view for better visibility, and even hidden components of the furniture can be zoomed and viewed. Product configuration tools (Zhang, 2014) is another technology that enables the company to provide the customer with a positive experience with the furniture, and also enables the highlighting of the features that the competitor products may lack. Augmented Reality (AR) (Phan & Choo, 2010) with all the associated XR technologies offers immersive near-life experience to the customer about the use of furniture and the comforts it can provide. While these are some of the technologies on the marketing side of the product, there are also technologies that can help the optimization of manufacturing resources. For instance, Building Information Modelling (BIM) (Sebastian, 2010) technology can enable the completion of the projects in lesser time by using the intelligent objects which are available in the database and can be used without building them from scratch, thus saving time and other resources. Computer-Aided Design (CAD) (Döngel et al., 2009) enhances the digital imagery for customers from the design to the manufacturing stage, and the customers can get the products of their choice by modifying the size and shape of the furniture to fit into their requirements.” All these technologies have to be managed for the benefit of the manufacturer and ultimately, they influence the perceived usefulness (PRU) of the customers, which is the most essential component of the TAM model.

The two basic elements of TAM are perceived ease of use (PEU) and the perceived usefulness (PRU), which determine whether a technology will be accepted or rejected in a given context. On the other hand, the basic two elements of the SECI model are tacit knowledge (TCK) and explicit knowledge (EXK), which drive innovation. So, in the hybridized model, knowledge and technology are the drivers, and innovation will be the outcome. The PEU of the technology used in the furniture design will be mainly in terms of its ability to handle the large amount of data pertaining to customer preferences in terms of the dwelling place. It could be the demographic details, lifestyles, activities performed in the room under design, age group of people who dwell in that room, special needs for hobbies or extracurricular activities, goals to be achieved in that room, color preferences, artwork, technical needs such as – surround sound, Wi-Fi, home theatre, computer, projector, etc. (Bao et al., 2022). The PEU is a function of both the rate at which these customer preferences increase and the rate at which the preferences become outdated and obsolete. So, the PEU will be associated with the design data growth rate and the design data archive rate. The causal relationship is shown in Figure 2. The circular causal loop exists in the PEU as shown in parentheses.

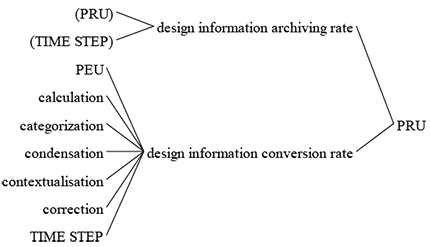

Figure 2

Causal Diagram of PEU

The PEU is the causal variable to the design information conversion rate. “While the PEU is contingent on ease of data handling, the PRU will be contingent on the usefulness of knowledge management. The central focus of the hybridized model is on the rate of design information conversion rate. The furniture design information could be in many different ‘forms’ that include: inorganic forms (geometric forms), organic forms (those of nature), open forms (outlines of the object), and closed forms (not visible from the outside). There is a systematic process to govern the conversion of this information into a digital form. The efficacy of this process is mainly based on five factors: calculation, condensation, categorization, contextualization, and correction. There are various calculations involved in the conversion of abstract information gathered through the personal preferences of the customers and in the development of the visual sphere (Bandeira Araújo et al., 2019). The furniture designers use different information visualization tools to understand users’ daily activities, and there are several calculations that are involved in the development of the visual image of the ‘forms’ that suit the liking of the customer. Condensation of the data is another aspect that has a bearing on the design information conversion rate. During the information condensation, the images are converted into some abstract form that is representative of the image, and it is important that there is no distortion of the original image when it is recalled (Fowler et al., 2001). During furniture design, concept development categorization plays a role in the design information conversion rate. During the design information categorization, retrieval, association, and transformation have to take place (Finke et al., 1992). Contextualization of furniture design is mainly in terms of ‘sustainability’, and all of its dimensions have to be considered for its effectiveness (Celadyn et al., 2019). The applicable statutory norms and environmental issues may play a vital role in contextualizing the design. In the design information conversion rate, correction also has a role to play. Correction refers to the rearrangement of the existing elements in the room without breaking the structure (Zhang & Xing, 2021). The information that can facilitate correction has to be processed very efficiently, and the most relevant data/information may have to be applied during the process of correction during the furniture design for the best results. In the hybridized model under consideration, these five factors which influence the design information conversion rate have been considered with their efficiencies varying from 20% to 80% in steps of 20%.” The causal diagram of the PRU is shown in Figure 3. It has to be noted that there is a circular causality in the PRU that is shown within parentheses.

Figure 3

The Causal Diagram of PRU

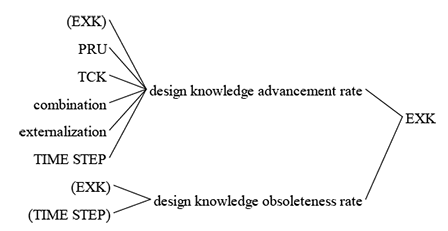

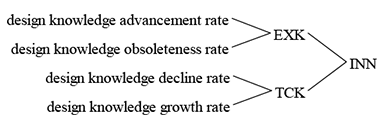

The linkage between the TAM and SECI models is through the PRU, which influences the design information archiving rate and design knowledge advancement rate. The EXK in the organization at any point in time is the remainder of the design knowledge advancement rate and design knowledge obsolescence rate. The causal diagram of EXK is shown in Figure 4 with the circular causality indicated by the parentheses.

Figure 4

The Causal Diagram of EXK

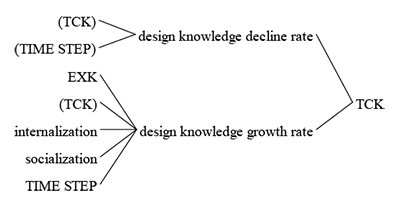

The SECI model is basically a knowledge conversion model with a structured approach to convert TCK that is hidden in the minds of people to EXK that can be codified and made available for the use of people in the organization for the creation of innovative products or processes. The causal diagram of TCK is shown in Figure 5 with circular causality indicated by parentheses.

Figure 5

The Causal Diagram of TCK

The INN taking place in the organization is the result of the conversion of the TCK to EXK, and there is cyclic causation between the four basic processes. The causal diagram of INN is shown in Figure 6.

Thus, the knowledge conversion is through socialization, externalization, combination, and internalization as shown in the hybridized model (Figure 1). The corresponding equations for these relationships are given in the Appendix.

Figure 6

The Causal Diagram of INN

3.3 The Base Run of the Model

The base run of the model is for the data obtained through the Furniture Design Organization under consideration. The current situation of the organization under consideration is that innovations taking place on a monthly basis vary from about 100 to 600, which include both product and process innovations, and the organization has introduced KMS to identify, assimilate, validate, store, distribute, and apply the knowledge for the benefit of the organization. These innovations were in several forms. For instance, Morpholio software was one such innovation where the industry permitted the insertion of some of the most iconic pieces of furniture into customers’ homes through a few clicks. In this research, only the five main factors which influence the rate of design information conversion have been considered to be the exogenous variables of interest that trigger innovativeness, and the variables associated with each of these factors have been highlighted in earlier sections. The base run of the simulation was with 20% efficiency of these five factors case by case. The innovation dynamics was simulated for an increase in the efficiency of these factors in steps of 20% to reach 80%, which is considered to be the upper limit.

4. Results, Analysis, and Discussions

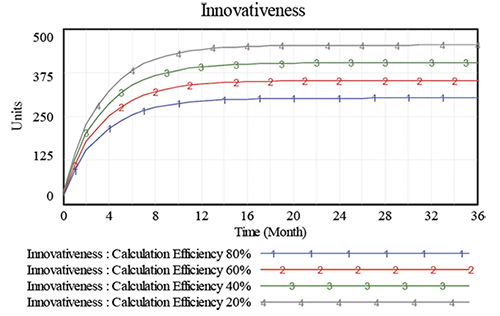

4.1 Influence of Calculation Efficiency on Innovation

It can be observed that the system stabilizes in about a year, with the increase in calculation efficiency, after which there will be a marginal improvement in innovativeness with the increase in calculation efficiency for the rest of the period (Figure 7). It can be observed that if calculation efficiency increases to 60%, in a span of a year, innovativeness as measured in terms of the number of innovations will improve by about 50%. Further, it can also be observed that even though the difference in the increase in innovativeness with the increase in calculation efficiency is marginal initially (for the period of about 2 months), it increases linearly with the increase in calculation efficiency and stabilizes thereafter. More precisely, with an increase in calculation efficiency from 20% to 80% in a span of a year, about 300 to 450 innovations can be achieved in furniture design.

Figure 7

Influence of Calculation Efficiency on Innovation

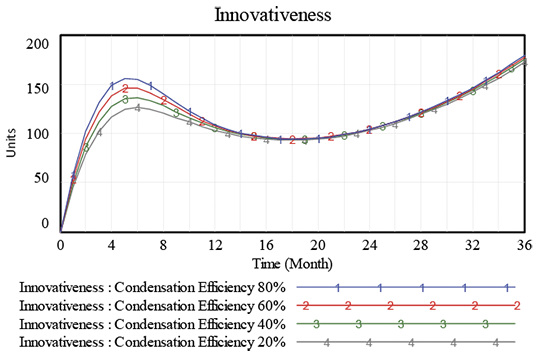

4.2 Influence of Condensation Efficiency on Innovation

It can be observed that with condensation efficiency enhancement, the system peaks out in about half a year, and it takes some time to realign itself during which innovativeness may be reduced to about 100 in 1 year and 2 months, and thereafter the innovativeness increases exponentially (Figure 8). During the peak period, if the condensation efficiency is increased to 60%, the innovativeness as measured in terms of the number of innovations will increase by about 28%. It can also be observed that the increase in condensation efficiency can influence the innovativeness only during the first year and after that even though the innovativeness of the firm increases exponentially, the rate of increase in condensation efficiency has no significant effect. The rate of increase in condensation efficiency provides a maximum of about 160 innovations within half a year.

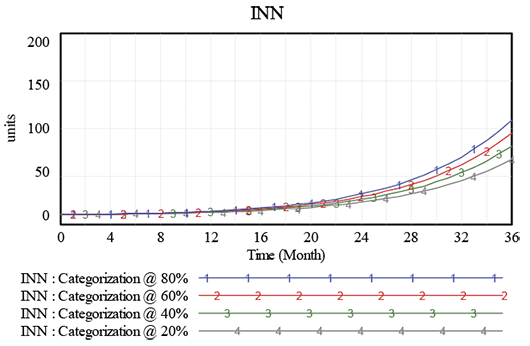

4.3 Influence of Categorization Efficiency on Innovation

It can be observed that the effect of the increase in categorization efficiency enhancement will surface only after about one and a half years of its implementation. Thereafter, there will be an exponential increase in innovativeness. In a span of about 3 years, if the categorization efficiency is improved to 60%, the innovativeness will be increased to about 83% (Figure 9). However, this approach will be able to bring about 110 innovations in a span of 3 years.

Figure 8

Influence of Condensation Efficiency on Innovation

Figure 9

Influence of Categorization Efficiency on Innovation

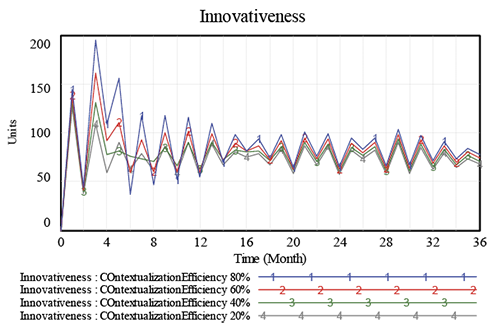

4.4 Influence of Contextualization Efficiency on Innovation

Among the variables under consideration, contextualization has demonstrated the most peculiar behavior. It can be observed that in the first 2 months variation in contextualization efficiency will not have a difference in innovativeness in terms of the efficiency variation; however, thereafter any increase in efficiency will also improve the innovativeness (Figure 10). While the difference in innovativeness will be higher initially, it will be less as time elapses. Maximum innovativeness can be observed in the third month, where about 200 innovations are found to increase the efficiency of contextualization to 80%, and about 110 innovations are introduced for a 20% efficiency improvement. Thus, in the third month of operation after implementing the improvement in contextualization efficiency, for a 60% improvement in efficiency an increase of about 82% in innovation can be achieved.

Figure 10

Influence of Contextualization Efficiency on Innovation

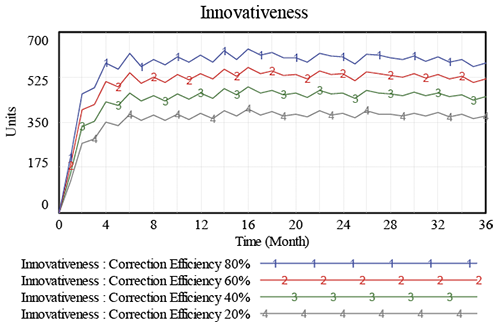

4.5 Influence of Corrections Efficiency on Innovation

Figure 11 shows that with the implementation of correction efficiency, the peak innovation can be reached in 6 months, and thereafter it fluctuates marginally. During this period, while an improvement in correction efficiency yields about 350 innovations, an 80% improvement in correction efficiency could bring about 615 innovations. Thus, with an improvement of correction efficiency of 60%, the corresponding increase in innovations will be about 76%.

Thus, it is clear from the simulation results that among the variables of the rate of design information management, the correction efficiency has the highest influence on the number of innovations that can be introduced in the products and processes, which is followed by the calculation efficiency. The least influence is observed in categorization efficiency, and it is followed by the condensation efficiency.

Figure 11

Influence of Correction Efficiency on Innovativeness

5. Implications and Suggestions

Furniture design is a very creative field and the survival of the industry is largely dependent on the drivers of innovation in products and processes. This research has both theoretical and practical implications. The theoretical implications are mainly in the form of the development of a model which is hybridized through the combination of the TAM and SECI models with a dimensional level of interdependence being established. The theoretical model has already been discussed earlier and the following specific suggestions are for the knowledge and technology managers as well as furniture designers in the organization.

The simulation results clearly indicate that improvement in the calculation efficiency in design information conversion rate by 60% leads to an increase of up to 50% in the innovativeness in products and processes in the furniture design. Effective furniture design service largely depends on the identification of the users’ needs and the delivery of the services as agreed between designers and users, which requires good design information transfer between the two parties. So, it is obvious that the furniture design managers should process the information obtained from the customers very effectively. ‘Information visualization’ holds the key to successful furniture design, and this involves the conversion of the abstract design information into a visual and metaphorical form. One of the challenges faced by the design information visualization researchers is the development of the visual sphere when the design information is in an abstract form and lacks space initiative. In other words, the objects, abstract data/information, and concepts have to be converted into images from the text form. While there are several technological tools available to accomplish this, the most common model that is used to serve this purpose is the ‘sphere activity change map’ (Chen, 2015), which is an information visualization tool that helps to understand users’ daily activities. A life-model-based design information tree that highlights the space spheres of individual family members and depicts the distribution of the average time family members spend in each space sphere will be developed using this tool. The suggestion to the managers is that they need to focus on the calculation efficiency during all the four stages of converting data into an image: namely-data/information collection and storage, data/information conversion into an intelligible form, graphic display of images, and observation and cognition. It is also advisable to identify the gap between the perceived and actual state during these calculations so that inaccuracies may be minimized on a continual basis.

Condensation efficiency when improved by 60% has the potential to increase innovativeness by 28%. Information condensation will gain importance specifically in the temporal dimension of furniture design, for instance, digital storage of furniture designs alleviates the problems posed by restrictions of physical space. So, the digitization process governed through condensation should be efficient as well as effective in promoting innovations in furniture design.

Improving categorization efficiency by 60% can increase innovativeness up to 83%. The categorization comprises retrieval, association, and transformation of data and information pertaining to the furniture design, and it has to cater to the ever-changing needs of the customers to be efficient. The furniture designers may focus on the basic elements of design information categorization viz., color, texture, form, etc., and then move to the higher-level descriptors such as sensorial, emotional, and product attributes.

A 60% increase in contextualization efficiency will improve innovativeness by about 82%. Contextualization in furniture design becomes important in sustainable furniture design which places emphasis on the environmental, economic, social, and cultural dimensions. When the focus is on the environment, the ecological effects of the object with minimum environmental degradation gain importance. Economic sustainability demands the minimum energy consumption in the process of furniture design and production. The occupant’s psychological and physical comfort could be of importance when social sustainability is in the focus. In addition to these, there are also cultural dimensions that are unique to the territory that needs to be considered during the contextualization of the design information pertaining to furniture design. There are several aspects that need the attention of furniture designers and their managers. First of all, the process of an environmentally friendly environment is not comprehensively defined as observed by the researchers (e.g., Celadyn, 2019; Jones, 2008; Sydor et al., 2021). This demands systematization and standardization of the processes involved in itemizing the activities involved in contextualizing the dimensions of sustainable furniture design. Furniture design methodology has to be updated with the elements of sustainable design, which demands a holistic approach considering the multi-dimensional approach with importance given to aspects such as integrative furniture design, interdisciplinary approach to design, evidence-based furniture design, and most importantly the research-based furniture design that is emphasized by researchers (e.g., Karan et al., 2021; Kim, 2021; Sydor et al., 2021). Multi-functionality of the elements of furniture design is another aspect that demands attention during contextualization. Multi-functionality to be considered includes the ability of the furniture design to satisfy the environmental and ecological dimensions. Contextualization of the furniture design in terms of these aspects could considerably spur innovation in this field.

The study shows that innovativeness can be increased by 76% if correction efficiency is improved by 60 %. Correction is an element that deals with the redesign of the physical space without breaking the walls or other physical structures, and correction efficiency has a bearing on innovations in processes and products. For instance, there are several innovative methods that are available in furniture design to make the space look enlarged, broadened, or heightened through optical illusions. There could be situations where customers specifically look into these aspects of furniture design, and correction efficiency plays an important role here.

Finally, when all the above factors in furniture design in terms of the information conversion paradigm are taken into account on a holistic basis, the most important factor to be considered by the furniture designers is correction efficiency enhancement. It is because when correction efficiency in design information conversion is increased to 80%, it can lead to as many as 615 innovations that include both process and product innovations in a span of 6 months after initiation of the process of improvement in efficiency. So, the implication of this research is that if the goal of the managers of a furniture design company is to maximize innovativeness, the focus should be on correction efficiency enhancement. The second factor that could significantly contribute to the product and process innovations is calculation efficiency, which can bring about as many as 450 innovations in a span of a year after the initiation. These two factors are very effective in terms of the number of innovations in products and processes. However, if the goal of the company is to have the highest possible innovations in the shortest possible time frame, then they need to focus on contextualization efficiency improvement, as it can generate about 200 innovations in a time as short as three months after initiation.

6. Conclusion

Innovation is driven both by the knowledge regarding the product or services offered by the organization and the technology that is available to convert the information to useful knowledge. So, there is a need to develop a hybridized model that combines TM and KM in the context of a creative organization that can be of use to other organizations with the appropriate modifications necessary. With these points in mind, the research work presented in this paper has the following conclusions which are derived through the simulation results undertaken based on the data available through a furniture design company.

First of all, to assess the efficiency and effectiveness of technology, we used the Technology Acceptance Model based on the PEU and PRU of the technology in the given context of business. In the case of KM, the two basic forms of knowledge which need to be exploited for organizational use are the EXK and TCK. The model shows that it is the PRU that contributes most to the advancement of design knowledge available in the organization. Further, PEU can contribute to the rate of change in the design data that is made available in the organization, which can in turn influence the design information conversion rate that will eventually lead to the design knowledge growth rate. It is the dynamics of these elements which can promote INN in the organization through the two forms of knowledge. This has been conceptualized in the hybridized model in the form of stock and flow diagrams in this research.

The research has identified correction efficiency and calculation efficiency as the most important factors when it comes to maximization of product and process innovations, whereas contextualization efficiency enhancement should be the priority if immediate results of innovativeness improvement are demanded.

This research has both theoretical and practical implications. Theory building in SD is a steady and continuous process. This research has developed a theoretical model that has established a linkage between the TM and KM in the hybridized form so as to spur innovation in the furniture industry. This model can also be generalized to other manufacturing industries with newer variables added as applicable to the specific industry. However, the core model can remain the same.

The practical implications of this research are for the furniture manufacturers. The SD model can be used to simulate the data to obtain the trends in the impact of calculation efficiency, condensation efficiency, categorization efficiency, contextualization efficiency, and corrections efficiency on innovation.

This research has focused on only five important factors which control design information conversion rate as identified by earlier researchers. This could be a limitation of the research as there could be other factors that can also influence the design information conversion rate. The generalization made in this research is purely based on the data obtained from a single furniture design company, and research on several such companies may be required to strengthen the reliability of the study results. The results are based on the SD modeling and simulation with its own limitations which are applicable to this research too.

To conclude, furniture design is a very creative field and the main driver of gaining a competitive edge in business in this field is the innovativeness of the products and processes involved in the design. The customers of today can use XR technologies to have a real feel of the furniture in their homes and to visualize what additional utility it can provide, and they look for the most creative artifacts. So, to meet these ever-changing needs and tastes of the customers there is a need to promote innovativeness through creative design, and the five factors considered in this research hold the key to success. The outcome of the research could be useful to both academicians and practitioners as it is based on real-time data. Thus, the research is timely and contributes both to theory and practice.

Acknowledgements: This work was in part supported by the Framework Agreement between the University of Pitesti (Romania) and King Mongkut’s University of Technology North Bangkok (Thailand), in part by the International Research Partnership “Electrical Engineering – Thai French Research Center (EE-TFRC)” under the project framework of the Lorraine Université d’Excellence (LUE) in cooperation between Université de Lorraine and King Mongkut’s University of Technology North Bangkok, in part by the National Research Council of Thailand (NRCT) under Senior Research Scholar Program – Grant No. N42A640328, and in part by Subprogramme 1.1. under Institutional performance – Projects to finance excellence in RDI – Contract No. 19PFE/30.12.2021.

References

Acheampong, P., Zhiwen, L., Antwi, H. A., Otoo, A. A. A., Mensah, W. G., & Sarpong, P. B.(2017). Hybridizing an Extended Technology Readiness Index with Technology Acceptance Model (TAM) to Predict E-payment Adoption in Ghana. American Journal of Multidisciplinary Research, 5(2), 22–38. https://onlinejournal.org.uk/index.php/ajmur/article/view/129

Acosta-Prado, J. C., Navarrete, J. F. F., & Tafur-Mendoza, A. A. (2021). Relationship Between Conditions of Knowledge Management and Innovation Capability in New Technology-Based Firms. International Journal of Innovation Management, 25(01), 2150005. https://doi.org/10.1142/S1363919621500055

Araújo, A., Rossi, A., & Fabián Olivero, L. (2019). Boxing the Visual Sphere: Towards a systematic solution of the cubical perspective. Conference: 41º Convegno Internazionale dei Docenti Della Representazione Congresso Della Unione Italiana per il Disegno, 33–40. https://doi.org/10.36165/1004

Bao, Z., Laovisutthichai, V., Tan, T., Wang, Q., & Lu, W. (2022). Design for manufacture and assembly (DfMA) enablers for offsite interior design and construction. Building Research & Information, 50(3), 325–338. https://doi.org/10.1080/09613218.2021.1966734

Casciani, D., Colombi, C., Chae, Y., & Jansen, K. (2021). Developing a Fashion-Tech Educational Model. Hybridizing design, engineering, and business management education. Global Fashion Online Conference, University of Warsaw, Poland, 21-22 October, 2021, pp. 1–19. http://hdl.handle.net/11311/1206565

Cefis, E., & Marsili, O. (2006). Survivor: The role of innovation in firms’ survival. Research Policy, 35(5), 626–641. https://doi.org/10.1016/j.respol.2006.02.006

Celadyn, M. (2019). Interior Architectural Design for Adaptive Reuse in Application of Environmental Sustainability Principles. Sustainability, 11(14), 3820. https://doi.org/10.3390/su11143820

Chen, C. H. (2015). Space Portrait: Establishment of a Lifestyle-Directed Visualized Model for Interior Design. Journal of Asian Architecture and Building Engineering, 14(1), 121–128. https://doi.org/10.3130/jaabe.14.121

Donate, M. J., & de Pablo, J. D. S. (2015). The role of knowledge-oriented leadership in knowledge management practices and innovation. Journal of Business Research, 68(2), 360–370. https://doi.org/10.1016/j.jbusres.2014.06.022

Döngel, N., Çınar, H., & Söğütlü, C. (2009). Design education: A case study of furniture and decoration education. Procedia–Social and Behavioral Sciences, 1(1), 2348–2353. https://doi.org/10.1016/j.sbspro.2009.01.411

Fernández-Portillo, A., Almodóvar-González, M., Sánchez-Escobedo, M. C., & Coca-Pérez, J. L. (2022). The role of innovation in the relationship between digitalisation and economic and financial performance. A company-level research. European Research on Management and Business Economics, 28(3), 100190. https://doi.org/10.1016/j.iedeen.2021.100190

Finke, R. A., Ward, T. B., & Smith, S. M. (1992). Creative Cognition: Theory, Research, and Application. Cambridge, MA: MIT Press. Retrieved on 8th August 2022 from https://mitpress.mit.edu/books/creative-cognition

Fowler, C. E., Shenton, W., Stubbs, G., & Mann, S. (2001). Tobacco Mosaic Virus Liquid Crystals as Templates for the Interior Design of Silica Mesophases and Nanoparticles. Advanced Materials, 13(16), 1266–1269. https://doi.org/10.1002/1521-4095 (200108)13:16%3C1266: AID-ADMA1266%3E3.0.CO; 2-9

Gloet, M., & Terziovski, M. (2004). Exploring the Relationship between Knowledge Management Practices and Innovation Performance. Journal of Manufacturing Technology Management, 15(5), 402–409. https://doi.org/10.1108/17410380410540390

Grissemann, U., Plank, A., & Brunner-Sperdin, A. (2013). Enhancing business performance of hotels: The role of innovation and customer orientation. International Journal of Hospitality Management, 33(1), 347–356. https://doi.org/10.1016/j.ijhm.2012.10.005

Heydari, S., TaheriKia, F., & ImanKhan, N. (2021). Developing a Framework to Integrate Customers’ Knowledge Management and Customer Relationship Management in the Banking Industry. Journal of Business Management, 13(2), 572–608. https://doi.org/10.22059/JIBM.2021.313655.3990

Isinkaye, F. O., & Soyemi, J. (2021). An Efficient Integration of Knowledge Management and E-learning in a Portable Interactive System. International Journal of Intelligent Information Systems, 10(3), 23–30. https://doi.org/10.11648/j.ijiis.20211003.11

Jones, L. (2008). Environmentally responsible design: Green and sustainable design for interior designers. John Wiley & Sons. Retrieved on 8th August 2022 from https://www.wiley.com/enie/Environmentally+Responsible+Design:+Green+and+Sustainable+Design+for+Interior+Designers-p-9780471761310

Karan, E., Asgari, S., & Rashidi, A. (2021). A Markov Decision Process Workflow for Automating Interior Design. KSCE Journal of Civil Engineering, 25(9), 3199–3212. https://doi.org/10.1007/s12205-021-1272-6

Kim, M. K. (2021). Affordance-based interior design with occupants’ behavioural data. Indoor and Built Environment, 30(9), 1373–1389. https://doi.org/10.1177/1420326X20948015

Koster, F. (2022). Knowledge Management and Innovation Performance a Mediated-Moderation Model. International Journal of Innovation and Technology Management, 19(02), 2250002. https://doi.org/10.1142/S021987702250002X

Lai, J. Y., Wang, J., Ulhas, K. R., & Chang, C. H. (2022). Aligning strategy with knowledge management system for improving innovation and business performance. Technology Analysis & Strategic Management, 34(4), 474–487. https://doi.org/10.1080/09537325.2021.1907328

Lee, H. J. (2016). Study of Furniture Design Utilizing 3D Printers Joris Laarman. Journal of the Korea Furniture Society, 27(2), 128–136. https://koreascience.kr/article/JAKO201614652521906.page

Limsangpetch, V., Siripipatthanakul, S., Phayaphrom, B., & Limna, P. (2022). Modelling Knowledge Management on Business Performance through Mediating Role of Organisational Innovation Among IT Staff in Bangkok, Thailand. International Journal of Behavioral Analytics, 2(2), 1–17. https:////papers.ssrn.com/sol3/papers.cfm?abstract_id=4036591

Lin, T. C., & Huang, C. C. (2008). Understanding knowledge management system usage antecedents: An integration of social cognitive theory and task technology fit. Information & Management, 45(6), 410-417. https://doi.org/10.1016/j.im.2008.06.004

Ngo, L. V., & O’cass, A. (2013). Innovation and business success: The mediating role of customer participation. Journal of Business Research, 66(8), 1134–1142. https://doi.org/10.1016/j.jbusres.2012.03.009

Peykani, P., Namazi, M., & Mohammadi, E. (2022). Bridging the Knowledge Gap between Technology and Business: An Innovation Strategy Perspective. PloS one, 17(4), e0266843. https://doi.org/10.1371/journal.pone.0266843

Phan, V. T., & Choo, S. Y. (2010). Interior Design in Augmented Reality Environment. International Journal of Computer Applications, 5(5), 16–21. https://doi.org/10.5120/912-1290

Silva, L., Rossi, R., Freitag, M. S., & Grzybovski, D. (2022). The role of knowledge management practices in the absorptive capacity: A research of soybean farms. Knowledge Management Research & Practice, 1–11. DOI:10.1080/14778238.2022.2141146

Sebastian, R. (2010). Integrated Design and Engineering Using Building Information Bodelling: A Pilot Project of Small-Scale Housing Development in the Netherlands. Architectural Engineering and Design Management, 6(2), 103–110. https://doi.org/10.3763/aedm.2010.0116

Sydor, M., Bonenberg, A., Doczekalska, B., & Cofta, G. (2022). Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers, 14(1), 145. https://doi.org/10.3390/polym14010145

Ullah, N., Al-Rahmi, W. M., Alfarraj, O., Alalwan, N., Alzahrani, A. I., Ramayah, T., & Kumar, V. (2022). Hybridizing cost saving with trust for blockchain technology adoption by financial institutions. Telematics and Informatics Reports, 6, 100008. https://doi.org/10.1016/j.teler.2022.100008

Wang, H., Zhou, W., Li, Y., & Li, Y. (2023). Business process digitisation and firm innovation performance: The role of knowledge search and digital culture. Knowledge Management Research & Practice, 1–12.

Zhang, C. Q., & Xing, H. T. (2021). Colour correction method of interior decoration engineering based on dense convolution neural network. International Journal of Arts and Technology, 13(2), 108–122. https://doi.org//10.1504/IJART.2021.120595

Zhang, L. L. (2014). Product configuration: a review of the state-of-the-art and future research. International Journal of Production Research, 52(21), 6381–6398. https://doi.org/10.1080/00207543.2014.942012

Zighan, S., & Dwaikat, N. Y. (2020). Exploring organisational agility in SMEs. The International Journal of Entrepreneurship and Small Business, 49(4). https://doi.org/10.1504/IJESB.2023.132854

Appendix

Equations

(01) calculation= accuracy of form reproduction*software efficiency of image processing

(02) categorization= design information recording efficiency*retrieval efficiency*association efficiency*transformation efficiency

(03) combination= socialization factor*internalization factor*externalization factor

(04) condensation= image conversion efficiency*image recall efficiency

(05) contextualisation= statutory norms coding efficiency*environmental factor coding efficiency

(06) correction= item rearrangement efficiency*retrofitting efficiency*space utilization efficiency

(07) design data archiving rate=0.1*PEU/TIME STEP

(08) design data growth rate=0.2*PEU/TIME STEP

(09) design information archiving rate=0.075*PRU/TIME STEP

(10) design information conversion rate= (0.6*calculation+0.8*categorization+0.2*condensation+0.9*contextualisation +5*correction)*PEU/TIME STEP

(11) design knowledge advancement rate=((combination*(EXK+PRU))+(externalization*TCK))/TIME STEP

(12) design knowledge decline rate=0.025*TCK/TIME STEP

(13) design knowledge growth rate=((EXK*internalization)+(TCK*socialization))/TIME STEP

(14) design knowledge obsoleteness rate= 0.4*EXK/TIME STEP

(15) EXK= INTEG (design knowledge advancement rate-design knowledge obsoleteness rate, 0)

(16) externalization=0.1

(17) FINAL TIME = 36

(18) INITIAL TIME = 0

(19) INN=EXK+TCK

(20) internalization=0.1

(21) PEU= INTEG (design data growth rate-design data archiving rate, 1)

(22) PRU= INTEG (design information conversion rate-design information archiving rate, 1)

(23) SAVEPER = TIME STEP

(24) socialization=0.1

(25) TCK= INTEG (design knowledge growth rate-design knowledge decline rate, 0)

(26) TIME STEP = 1